TM 11-6625-486-14&P

OPERATOR'S AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. TOOLS AND EQUIPMENT

4-1. General

Tools and equipment required for operator and

organizational maintenance are listed in appendix C.

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4-2. General

To insure that the frequency meter is always ready for

operation of the unit will be noted for future correction to

operation, it must be inspected systematically so that

be made as soon as operation has ceased. Stop

defects can be discovered and corrected before they

operation immediately if a deficiency is noted during

result in serious damage or failure. The necessary

operation which would damage the equipment. Record

preventive maintenance checks and services to be

all deficiencies, together with the corrective action

performed are listed in tables 4-1, 4-2, and 4-3. The

taken, in accordance with TM 750-8. item

numbers indicate the sequence of and minimum

inspection required. Defects discovered

during

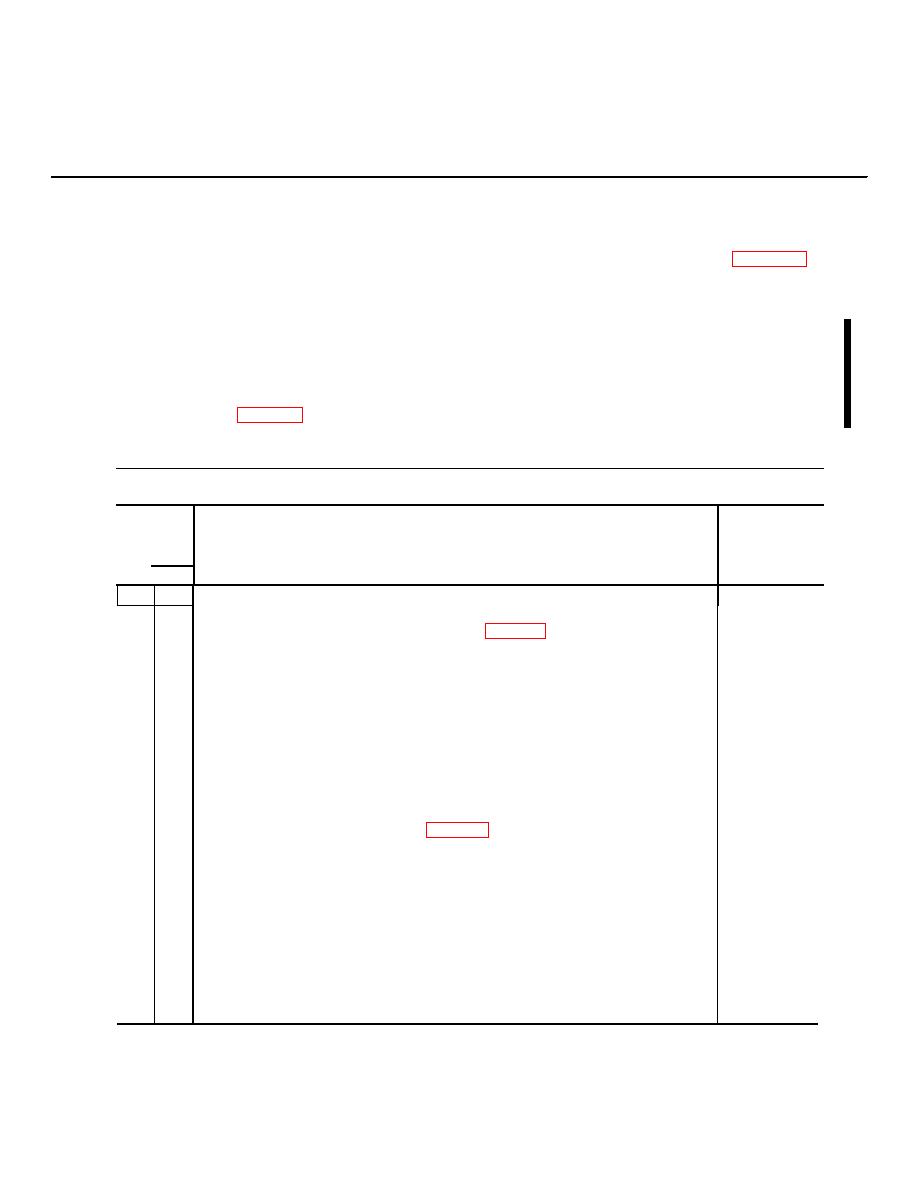

D--Daily

W--Weekly

Time required: 0.5

Time required: 0.2

Interval

Items to be inspected

and

sequence

Work

____ no. ___

Procedures

time

(M H)

D

W

1

0.1

Check to see that the equipment is complete (table 1-1).

2

EXTERIOR SURFACES

0.1

Clean the exterior surfaces, including the panel and meter glass. Check the meter

and film readout glasses for cracks.

3

CONNECTORS

Check the tightness of all connectors.

4

CONTROLS AND INDICATORS

While making the operating checks (item 5) observe that the mechanical action of

each knob, dial, and switch is smooth and free of external or internal binding, and

there is no excessive looseness. Also, check the meter for sticking or bent pointer.

5

OPERATION

0.3

Operate the equipment according to table 4-4.

1

CABLES

0.1

Inspect cords, cables, and wires for chafed, cracked, or frayed insulation. Replace

connectors that are broken, arced, stripped, or excessively worn.

2

HANDLES AND LATCHES

Inspect handles, latches, and hinges for looseness. Replace or tighten as

necessary.

3

METAL SURFACES

0.1

Inspect exposed metal surfaces for rust and corrosion. Clean and touch up paint as

required.

4

BATTERY COMPARTMENT

Inspect the batteries for leakage. Check the compartment for corrosion.

Previous Page

Previous Page